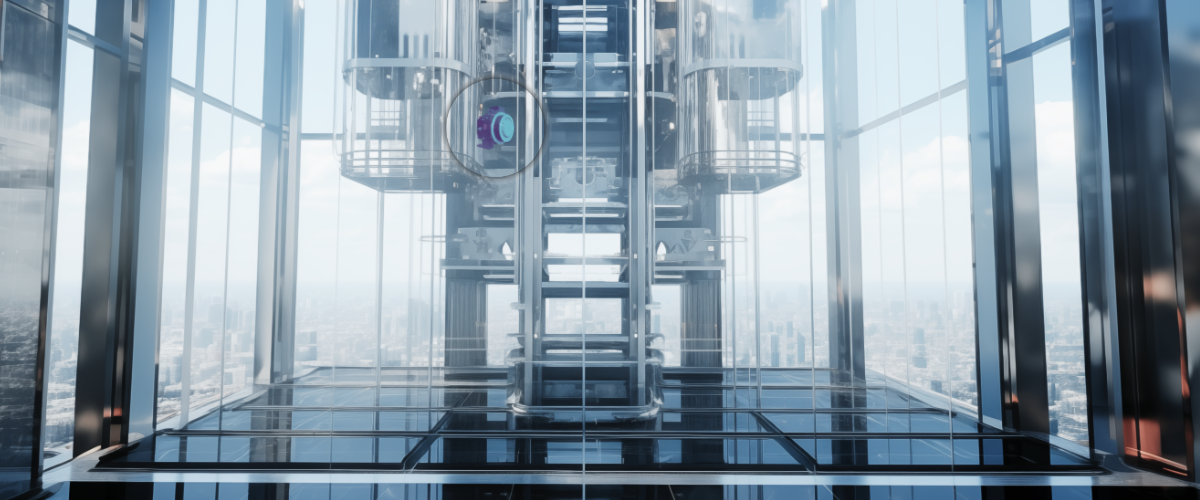

Specialized Encoders

Special encoders are built-in bearing absolute rotary encoders designed for elevators and other applications requiring high-precision position feedback. Elevator applications include the main drive motor, car door motor, and shaft positioning system. With the support of Transzhou Technology's encoder chips and system solutions, these encoders effectively address challenges related to safety and ride stability. The solution employs multiple redundancy designs and integrates intelligent compensation algorithms, which can automatically adjust to handle signal variations, temperature fluctuations, and aging effects. This makes it an ideal choice for elevator control systems, special machinery, and automation equipment.

-

01

Safety Redundancy

The inductive encoder chip features multiple redundancy designs, offering dual or multiple signal paths to ensure continued operation even in the event of a single-point failure. This high-reliability design is crucial for elevator safety, effectively preventing downtime or accidents caused by encoder failures and ensuring passenger safety.

-

02

Signal Variation, Temperature, And Aging Effect Compensation

Integrated intelligent compensation algorithms can automatically adjust to address signal variations, temperature fluctuations, and aging effects. By monitoring and correcting in real-time, they ensure long-term stability and accuracy, extend the lifespan of the elevator, and significantly reduce maintenance costs.

-

03

High Precision

With a design of up to 2048 lines, it achieves extremely high resolution and positioning accuracy, ensuring smooth changes in the acceleration of the elevator car. This reduces the stimulation to the vestibular system caused by acceleration fluctuations, making it especially suitable for elevator applications with very high stability requirements, and significantly enhancing passenger comfort.